Hello Pandas!

Here’s the story of my DIY project. I believe it may be helpful and inspire people to create designs for home with the soul.

Please enjoy and find me on Twitter!

Made with @LightBurnLaser & #endurancelasers (10W module with G7 lenses and v2 air assist nozzle), plus some cheap Chinese laser engraver with DIY air assist system.

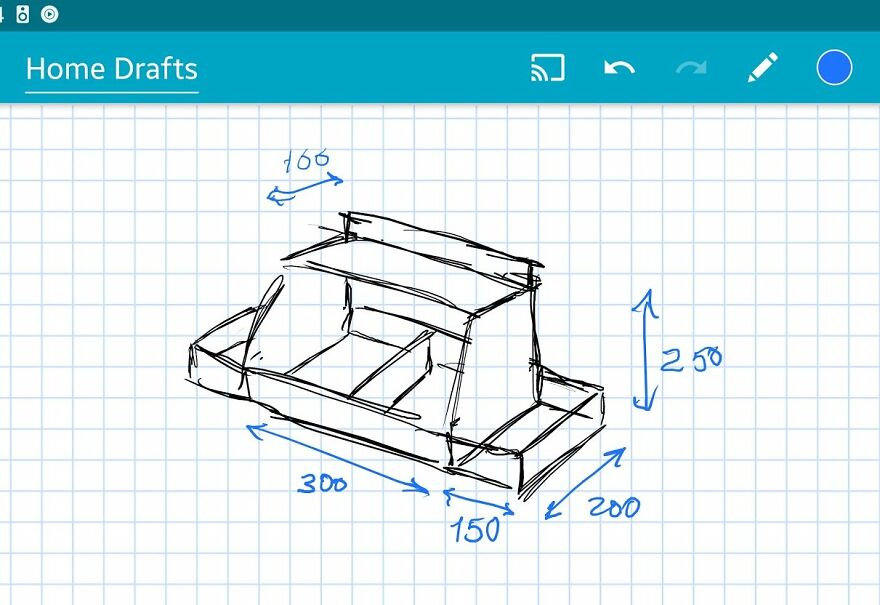

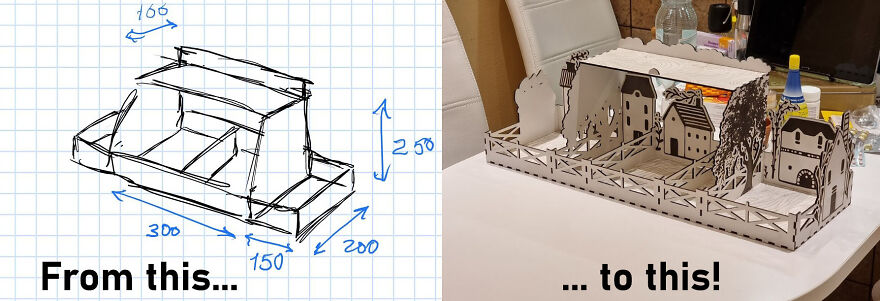

So, step 1, the sketch!

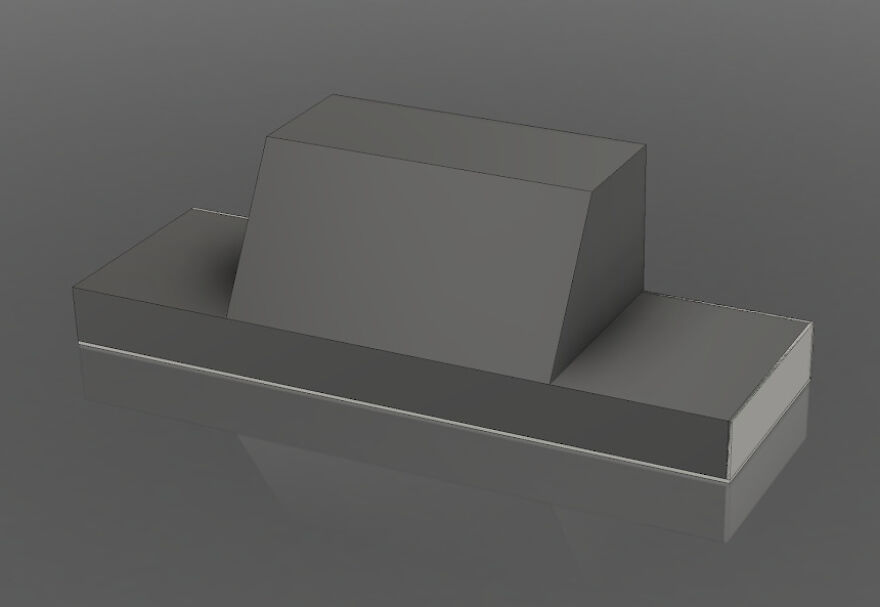

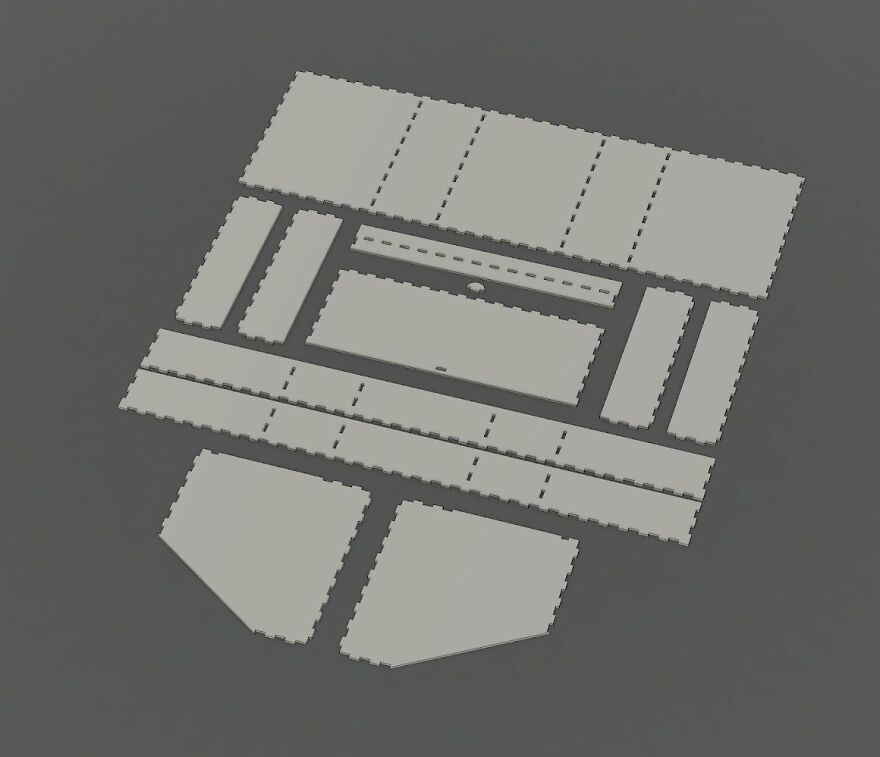

Step 2,fusion360, a box with base dimensions and shape

I never created models for laser cutting (and never learned how to build), so I tried to develop my own approach as this is the first but not the last model I will make.

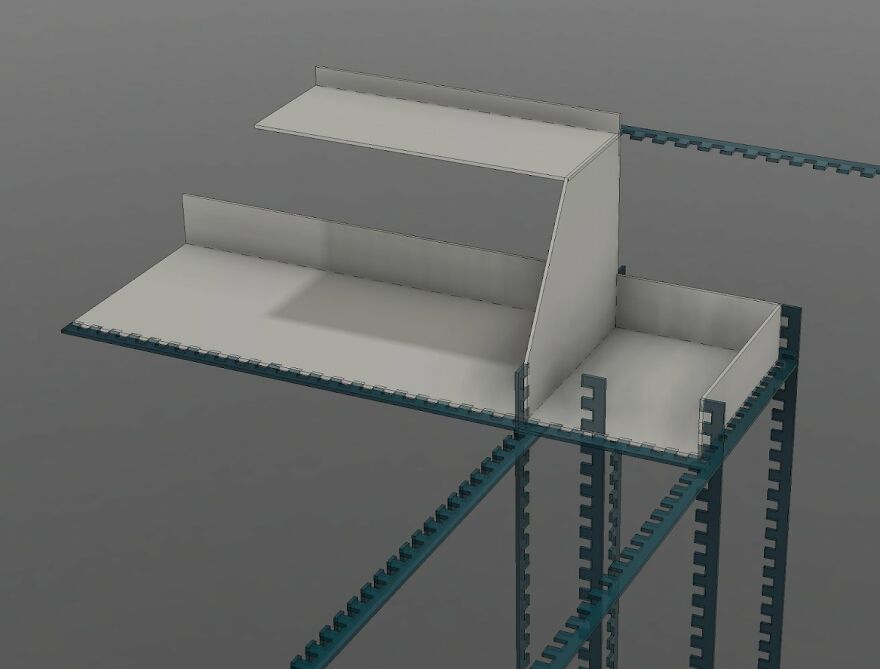

Step 3, assembly planning

I’ve been thinking a lot about making the groove cuts and making them parametric, so you can edit all at once and make the process repeatable in the future. I think I found a way.

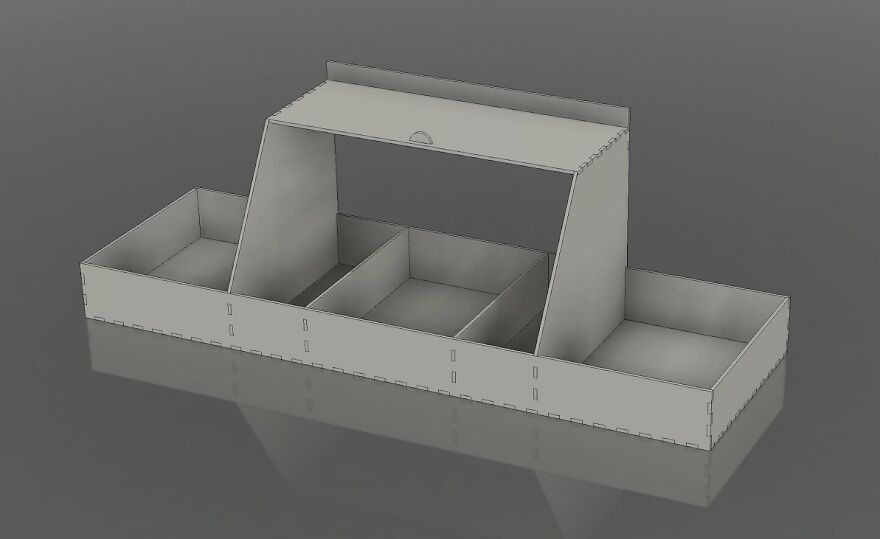

Step 4, final base model look

All the cuts are in place, the has-been model assembled. I had to change the design and dimensions a bit, but this was to be expected. And although the model uses expressions it was not so difficult to adjust it.

Step 5, sketch export

I used Shaper Utilities to export 3d models layout as a 2d vector sketch. Now it is ready for some magic.

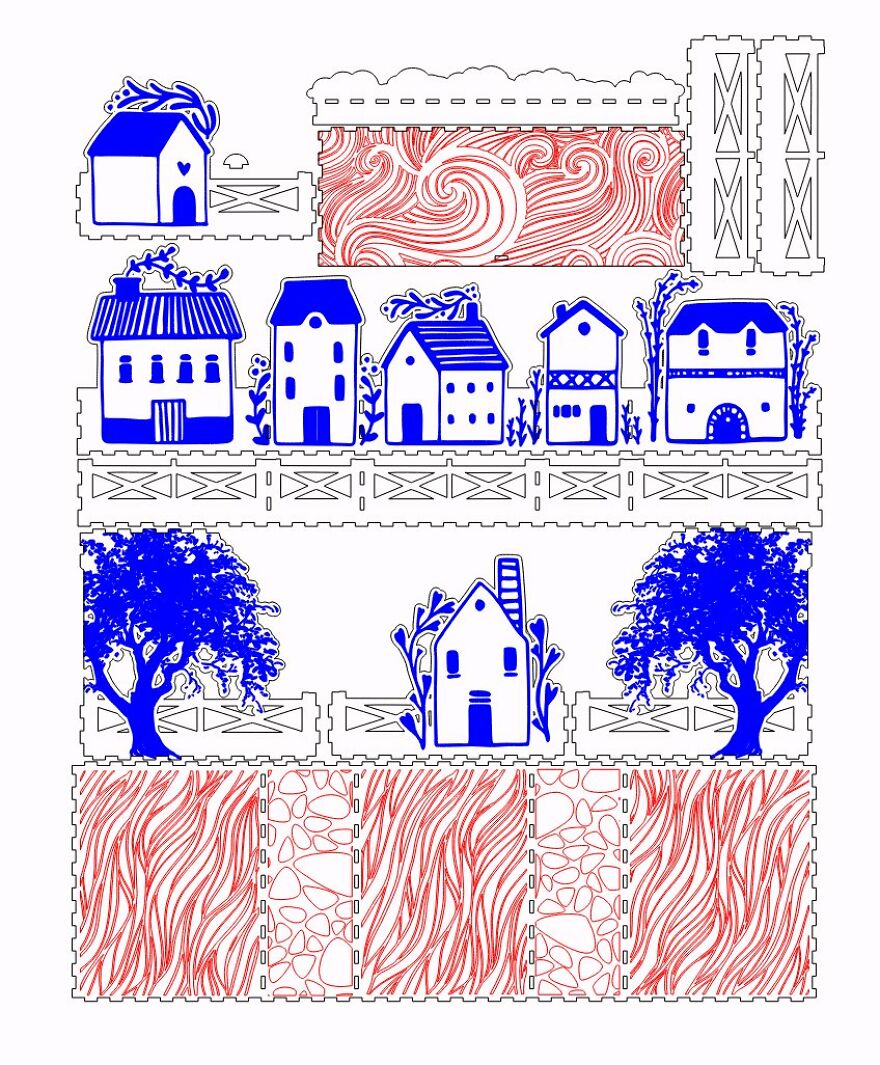

Step 6, the MAGIC!

I googled for some images to make the box more attractive. I used low-quality raster images, so I scaled them up and vectorized them. And after a few hours, I prepared a nice themed scheme for cutting and engraving.

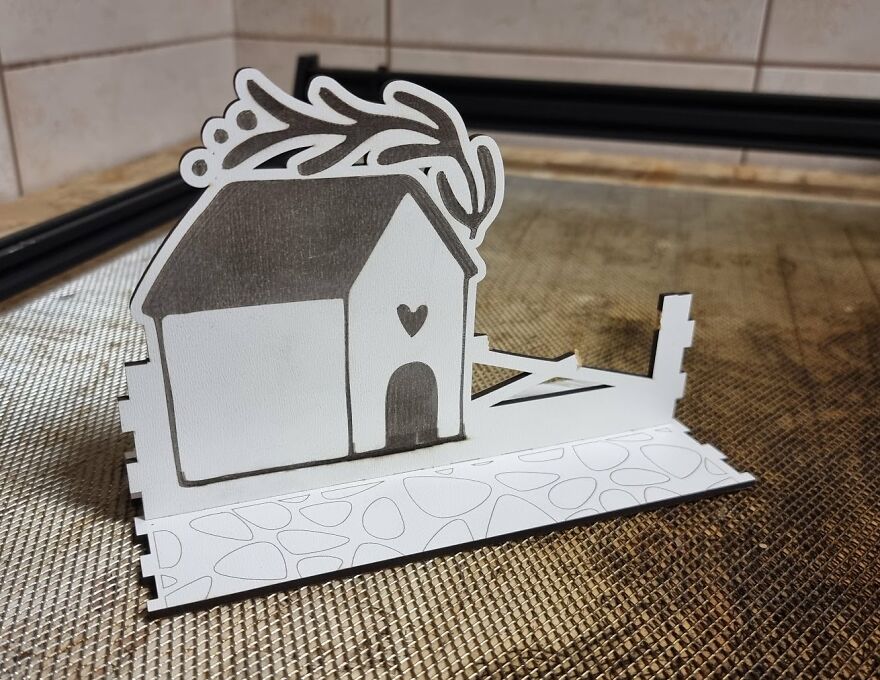

Step 7, the test

I set the engraving and cutting parameters and did a test run. And almost immediately discovered that the MDF is quite fragile, and I need to be careful when assembling it.

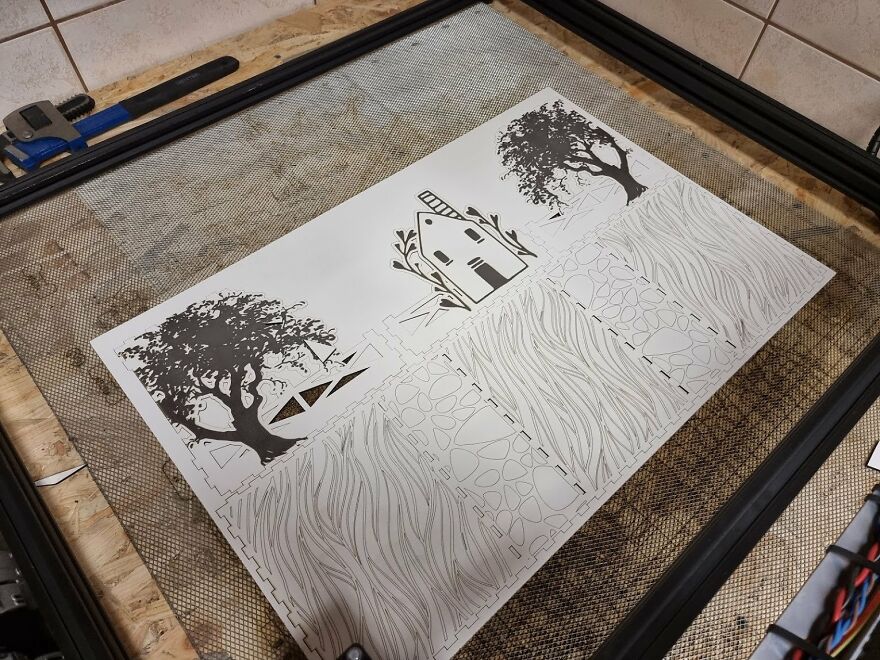

Step 8, cutting, part one of two

I chose a double-sided white laminated MDF with a thickness of 3mm and a size of 600x400mm per sheet. So I had to split the model into two parts. And here’s the first part.

Step 9, cutting, part two of two

On the second sheet, I make some minor changes to the final design.

Diode laser at work with DIY air assist unit

Step 10, assembly!

A couple of drops of white glue and simple parts attaching one by one. The easiest and the most enjoyable part of the job.

And finally, the RESULT!

Source link : https://www.boredpanda.com/instead-of-making-another-boring-diy-box-i-added-a-little-magic-and-lasers-to-it